Features and Benefits

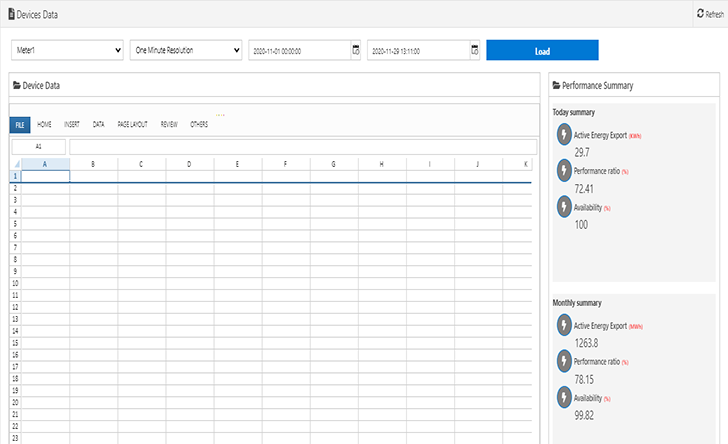

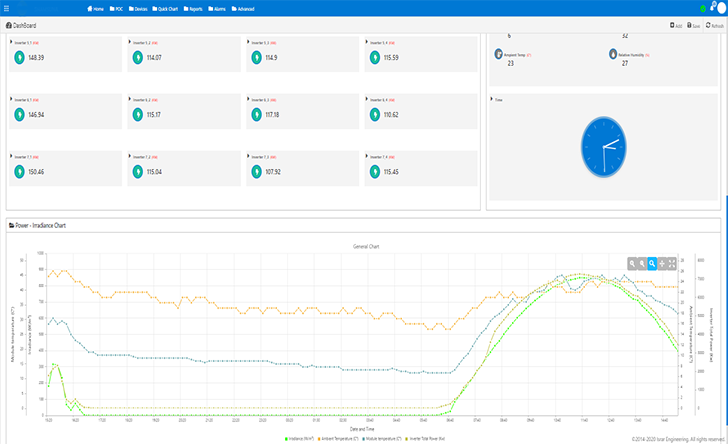

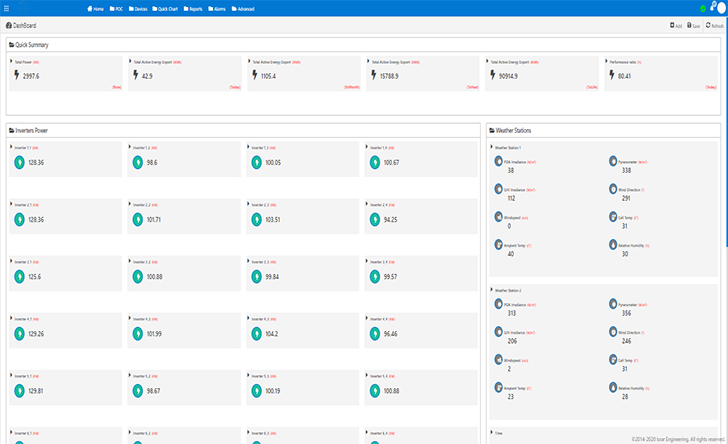

- This system monitor data from a numerous device, including meters, inverters, weather stations, trackers, DC strings and substation equipment

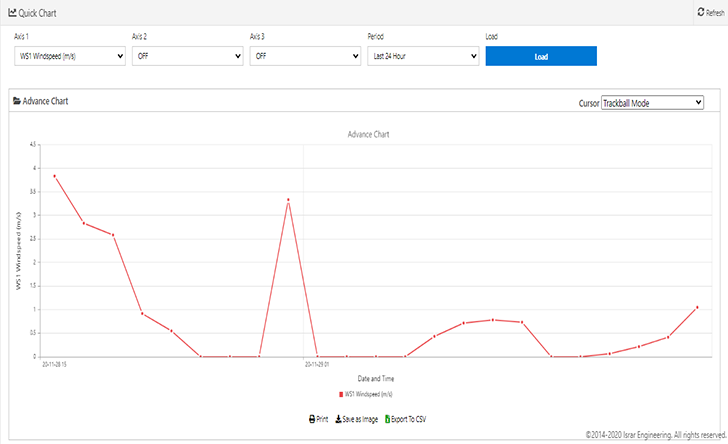

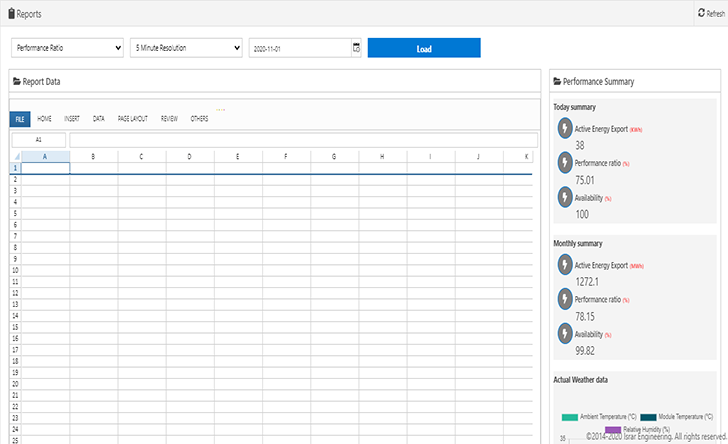

- System Contents: Databases, Webserver, Graphic curve, Reports and Raw-data

- Automated methods of identifying and addressing performance issues

- Manage multiple sites simplifying how owners run their sites

- Constantly monitor equipment at a site and record sampled data to a local datalogger server equipment

- Real-time data is visually represented on operator screens and is used to assess alarm conditions

- Advance Summary informative screen of the collected data to show trends and identify irregularities with showcase design queries and reports that summarize the data for operational maintenance and management

- Performance-based alarms to alert operators when a site, or individual devices within that site, are not performing optimally

- Customizable installation

- Totally scalable – simply upgraded through various tag levels with provision of a new software key